HVAC Equipment Analytics

Abound Predictive Insights provides predictive, actionable insights into the health of connected chillers, air handlers, rooftop units, VAV boxes, unit heaters, air conditioners, heat pumps, fan coil units, and refrigerated cases. With help from our experts, you can take advantage of reports with insights and recommendations to help proactively maintain the health of your HVAC equipment. Proactive maintenance strategies can then be deployed, helping to prevent failure and optimize equipment performance.

Key Features and Benefits

- Utilize an authorized Automated Logic representative as your trusted advisor for HVAC equipment maintenance

- Maintain piece of mind that your equipment is being proactively maintained

- Gain actionable insights from your Automated Logic representative directly through quarterly reports

- Receive predictive actionable insights for a single piece of HVAC equipment or your entire portfolio of HVAC equipment

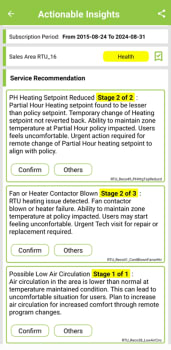

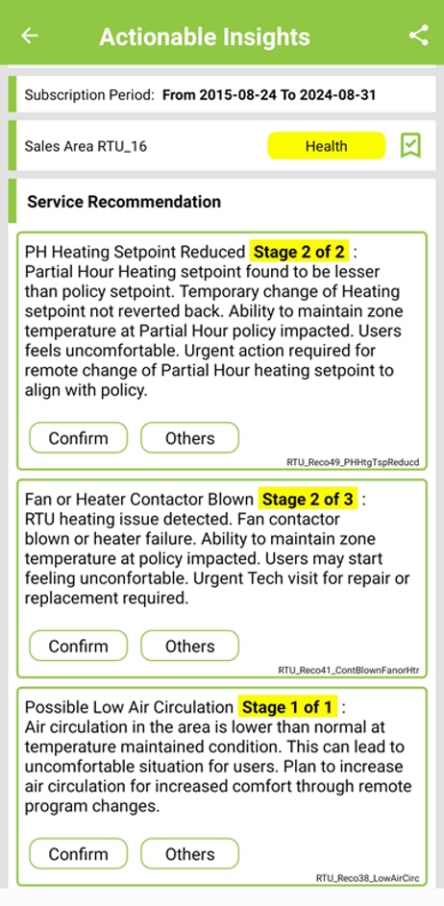

- Predictive actionable insights track equipment failure lifecycle in stages and provide recommendations at each stage – cause, impact, and how to correct

- Most tuning/fixes can be deployed remotely by the Automated Logic representative, without having to come on-site

- Helps improve equipment performance, increase reliability, and prevent failure

- Identify faults and inefficiencies before they become larger issues

- Trigger maintenance promptly to reduce disruption and costs of repair

- Reduce costly emergency repairs and truck rolls

- Reduce trouble calls from occupants/tenants

- Increase reliability and improve performance of HVAC equipment

- Reduce operations and maintenance costs

- Improve energy efficiency and occupant comfort

- Optimize capital expenditure planning

Sampling of Points Analyzed on Airside HVAC Equipment

- Communication

- Zone Temperature

- Supply Air Temperature

- Supply Fan Command/Status

- Compressor Command/Status

- Heater Command/Status

- Economizer Damper Position

- Cooling - Heating mode

- Zone Temperature Setpoint

- Economizer DB Temp High Limit

- Economizer DB Temp Low Limit

- Cooling Lockout Active Status/Cooling Lockout Setpoint

- Heating Lockout Active Status/Heating Lockout Setpoint

- Utilize an authorized Automated Logic representative as your trusted advisor for HVAC equipment maintenance

- Maintain piece of mind that your equipment is being proactively maintained

- Gain actionable insights from your Automated Logic representative directly through quarterly reports

- Receive predictive actionable insights for a single piece of HVAC equipment or your entire portfolio of HVAC equipment

- Predictive actionable insights track equipment failure lifecycle in stages and provide recommendations at each stage – cause, impact, and how to correct

- Most tuning/fixes can be deployed remotely by the Automated Logic representative, without having to come on-site

- Helps improve equipment performance, increase reliability, and prevent failure

- Identify faults and inefficiencies before they become larger issues

- Trigger maintenance promptly to reduce disruption and costs of repair

- Reduce costly emergency repairs and truck rolls

- Reduce trouble calls from occupants/tenants

- Increase reliability and improve performance of HVAC equipment

- Reduce operations and maintenance costs

- Improve energy efficiency and occupant comfort

- Optimize capital expenditure planning

- Communication

- Zone Temperature

- Supply Air Temperature

- Supply Fan Command/Status

- Compressor Command/Status

- Heater Command/Status

- Economizer Damper Position

- Cooling - Heating mode

- Zone Temperature Setpoint

- Economizer DB Temp High Limit

- Economizer DB Temp Low Limit

- Cooling Lockout Active Status/Cooling Lockout Setpoint

- Heating Lockout Active Status/Heating Lockout Setpoint