Specification Writing: A Productivity Tool

What do you like best about writing specifications? The creativity? Incorporating new technologies like BACnet? The certainty that this specification will be complete, and consistent? The truth is, very few engineers actually enjoy writing specifications. While the design process is technically challenging and provides limitless opportunity for innovation and creativity, when it comes time to translate that design into legally enforceable prose, the creative process is over. For most engineers, writing specifications becomes a “cut and paste” process, taking a document that’s worked in the past and updating it for the current project. The problem is that if you start with a document that’s worked in the past, you run the risk of overlooking opportunities provided by the latest technologies. If you start with a “guide specification” provided by a control system vendor, you run the risk of writing a proprietary specification that locks you into a single supplier. And if you start with a clean slate and write a specification from scratch, the research and proofreading required to make it complete and comprehensive becomes almost overwhelming. There must be a better way.

ASHRAE took a major step toward simplifying this process when they created ASHRAE Guideline 13-2000, “Specifying Direct Digital Control Systems.” This established a vendor neutral, professionally sanctioned framework for writing control system specifications, from sensor tolerances to graphical user interfaces. The guideline provides options and recommendations for the specifying engineer and by establishing an industry consensus it provides an excellent platform upon which to build a specification.

The ASHRAE guideline provides the basis for the general sections of the control specification; however, to be complete the specification should also define how each individual piece of equipment will be controlled and what information and adjustments will be available to the user. Typically, these details are provided in a sequence of operation and a points list for every unique type of equipment included in a project. The ASHRAE guideline provides a location to insert sequences and points lists, but makes no attempt to define the actual sequences. Traditional cut and paste techniques are not well suited to creating sequences and points lists, because the wide range of control options provided by most DDC systems leads to an almost infinite number of possible combinations. While these options make it easy to optimize control of the equipment, it is very unlikely that most engineers will have a “canned” specification that describes this sequence.

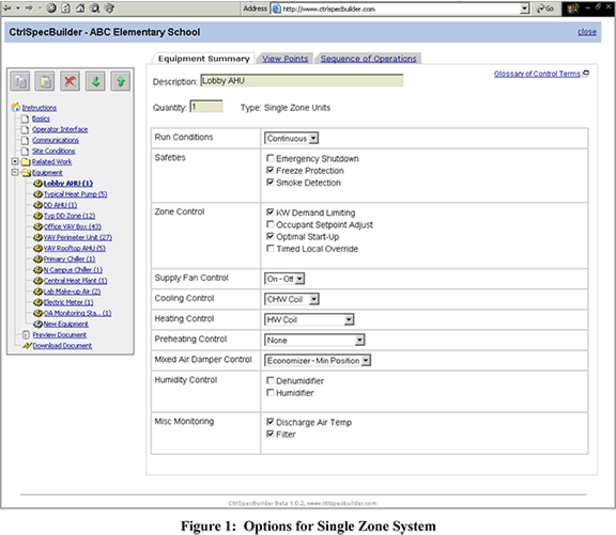

Automated Logic Corporation (ALC) has created the CtrlSpecBuilder® that is designed to solve this problem. Based upon the ASHRAE guidelines, it lets the user configure the general portion of the specification by answering questions about the scope of the project, communication protocol to be used, desired system-wide energy management features, and similar issues. The CtrlSpecBuilder tool then allows the user to create sequences of control and points lists for thousands of typical HVAC systems through a simple menu-driven interface. For example, select “Single Zone System” as the equipment type (See Figure 1) and you will be presented with a single page summary of control options for this system.

As shown in Figure 1, when you add a single zone system to your project you are presented with a default configuration that can be edited by clicking on checkboxes or drop lists. Although simple to comprehend and configure, this page actually provides 35 different control options which can create 70 billion possible combinations. Each option selected affects the sequence of operation and the points list for this equipment. Additionally, control parameters such as setpoints and reset schedules can be edited within the sequence of operation. There are 32 other types of equipment that can be configured in CtrlSpecBuilder tool, so the total number of unique control sequences that can be created with this tool is quite large.

Even a large selection of menu options can’t cover every possibility, so users can also create a custom sequence of operation and points list. This is more work than selecting one of the existing options, of course, so the web site’s designers have tried to cover all the most common control applications with the menu choices. Custom sequences should only be required for unusual situations. Once you have configured your equipment, you can download the specifications, sequences of control, and points lists as a Microsoft Word document.

What makes the CtrlSpecBuilder tool different from the guide specs published by other control manufacturers? There are four major differences:

- It’s based upon the ASHRAE guidelines.

- It’s open and non-proprietary.

- It provides options (not mandates) for BACnet, Web-based systems, and other new technologies.

- It’s an online tool that lets you configure a sequence of control for every piece of equipment in your project.

We’ve already discussed points 1, 3, and 4, but the second point needs a bit of explanation. Typically, when a control manufacturer prepares a sample specification it’s written around their own line of controls. The requirement to use their product may be stated outright or it may be “hidden” in dozens of technical details, but the net result is that their product is the only control system that meets this specification. Why doesn’t the CtrlSpecBuilder tool follow this model? Why would a manufacturer create a tool to write open specifications?

Rather than trying to “sell” a proprietary spec to a few cooperative specifying engineers and be locked into 100% of the jobs put on the street with that spec, Automated Logic is looking to help a much larger group of engineers write high quality open specifications, and letting the products compete on their own merits. That’s why they used the ASHRAE guidelines, that’s why the sequences of operation are non-proprietary, and that’s why they put the CtrlSpecBuilder tool on the web, to be used free of charge by any specifying engineer. The web site www.CtrlSpecBuilder.com is currently open to all users.